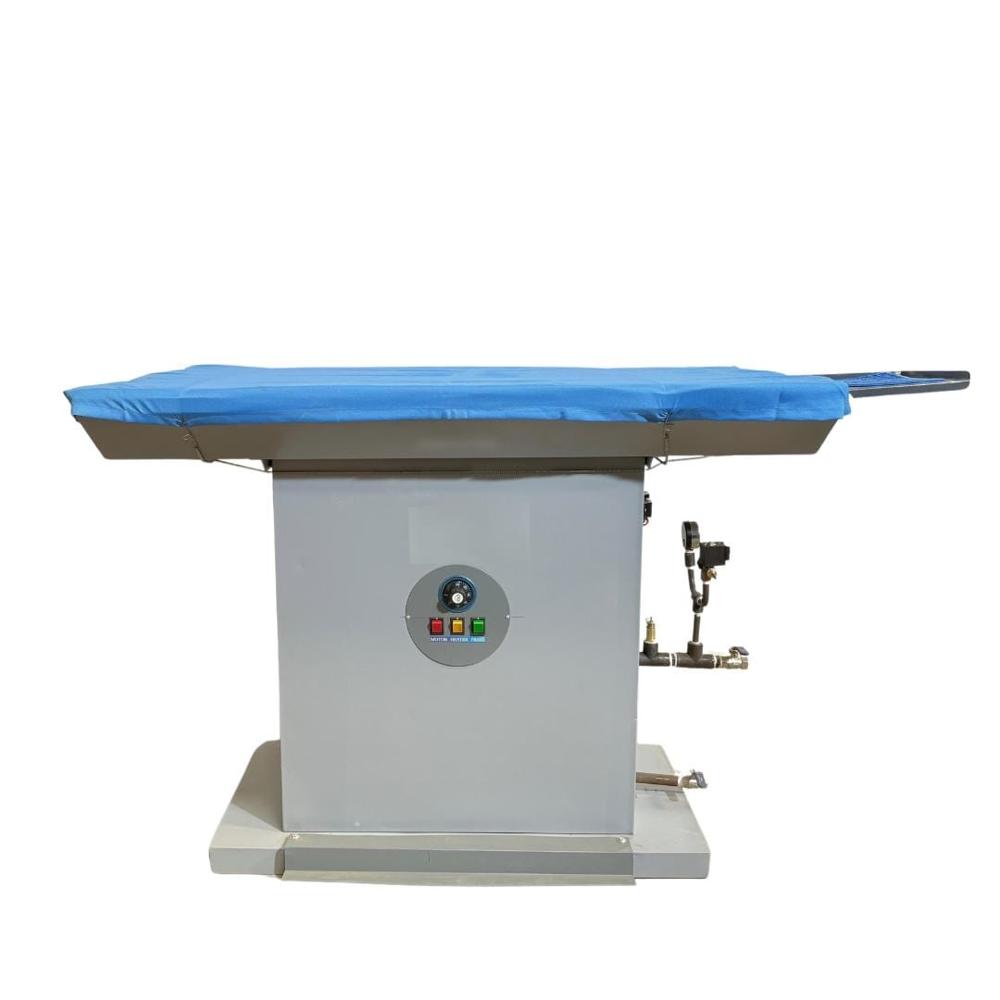

Vacuum Table With Inbuild Boiler

Product Details:

- Voltage 240 Volt (v)

- Weight 55 Kilograms (kg)

- Applicable Material SS

- Type Iron Table

- Dimension (L*W*H) 122*77*92 Centimeter (cm)

- Manufacturing Year 5 Days

- Click to View more

Vacuum Table With Inbuild Boiler Price And Quantity

- 1 Piece

- 45000.0 INR/Piece

Vacuum Table With Inbuild Boiler Product Specifications

- 122*77*92 Centimeter (cm)

- Iron Table

- SS

- 55 Kilograms (kg)

- 5 Days

- 240 Volt (v)

Vacuum Table With Inbuild Boiler Trade Information

- 7 Days

- No

- All India

Product Description

A vacuum table with inbuilt boiler is a specialized piece of equipment primarily used in the garment, textile, and laundry industries for professional ironing and pressing. It combines three key features: a vacuum surface, a heated working area, and a built-in steam boiler. Heres a detailed description:

Vacuum Table with Inbuilt Boiler Description

A vacuum table with inbuilt boiler is an all-in-one pressing station designed to streamline the garment finishing process. It features a perforated work surface that enables strong suction (vacuum), which helps hold garments in place during ironing and quickly removes moisture from fabrics. The integrated boiler produces a consistent supply of dry steam, which is delivered through a connected steam iron. This combination ensures efficient, high-quality pressing with reduced operator effort.

Key Features

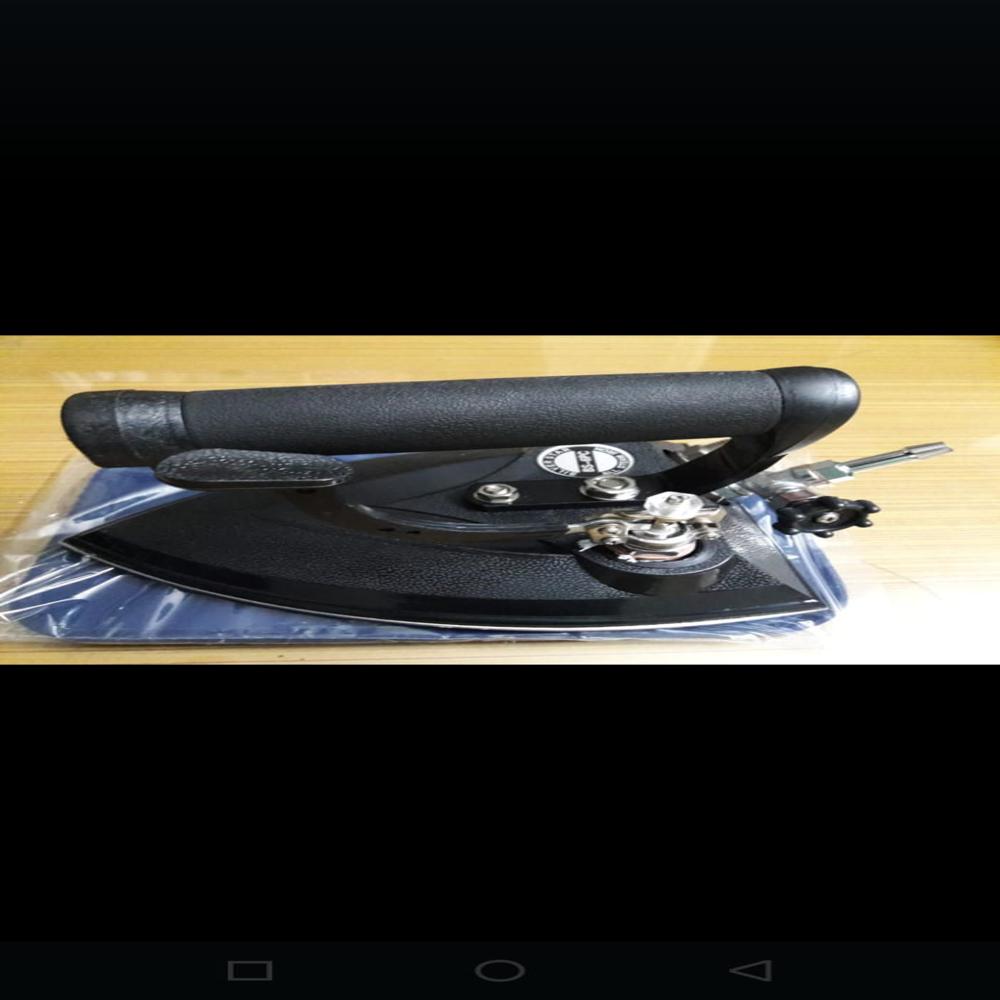

Vacuum Function:

A powerful suction motor draws air through the perforated table surface, helping:

Fix the garment in position

Remove steam and moisture during ironing

Reduce drying time and prevent re-wrinkling

Inbuilt Boiler:

The steam boiler, typically made of stainless steel, heats water to generate pressurized steam. It offers:

Continuous steam for extended ironing sessions

Adjustable pressure settings for different fabric types

Built-in safety features like pressure release valves

Heated Table Surface:

Some models have a thermostatically controlled heating element under the table surface to:

Keep the fabric warm

Aid in moisture evaporation

Improve the final finish of garments

Advanced Ironing Solution

The Vacuum Table with Inbuilt Boiler merges vacuum suction with integrated steam generation to deliver a superior pressing experience. Its robust construction using stainless steel ensures durability for continuous industrial use. Designed for both exporting and domestic manufacturing needs, this table guarantees exceptional garment finishing with minimal manual effort, enhancing productivity for businesses in the fashion and textile industry.

Efficient Manufacturing and Supply

Manufactured in India within a swift 5-day timeline, this product is readily available for businesses seeking prompt delivery and installation. Backed by expertise in exporting, manufacturing, supplying, and trading, the table supports varied business requirements. Its well-balanced size and design make it an optimal addition to factories and workshops with limited space but demanding workloads.

FAQs of Vacuum Table With Inbuild Boiler:

Q: How does the inbuilt boiler improve the ironing process on this vacuum table?

A: The inbuilt boiler provides consistent steam directly from the table, eliminating the need for external steam generators. This feature allows for seamless garment ironing as steam is delivered uniformly, resulting in improved fabric smoothness and enhanced pressing efficiency.Q: What are the ideal materials and settings for using the Vacuum Table with Inbuilt Boiler?

A: This ironing table is crafted from stainless steel, making it ideal for a variety of textile applications. The vacuum and steam features are particularly beneficial for cotton, linen, wool, and synthetic fabrics, allowing precise control and optimal results in garment finishing.Q: When can I expect delivery after placing an order for this product?

A: The Vacuum Table with Inbuilt Boiler is typically manufactured within 5 days. Delivery timings may vary based on your location and specific order requirements, but prompt processing is ensured to support your business timelines.Q: Where is the Vacuum Table with Inbuilt Boiler manufactured and supplied from?

A: This product is manufactured, exported, and supplied directly from India, ensuring local and international clients have access to reliable equipment for textile processing and garment finishing.Q: What is the process for installing and using this vacuum table?

A: Installation involves placing the table in a flat workspace, connecting to a 240-volt power supply, and filling the built-in boiler with water. Once powered, the table quickly becomes operational, enabling users to commence garment ironing with integrated vacuum and steam functionality.Q: What are the main benefits of using a Vacuum Table with Inbuilt Boiler in a textile operation?

A: Utilizing this table streamlines garment finishing by combining vacuum suction and direct steam, resulting in faster, more professional ironing performance. The robust stainless steel construction ensures durability, while its efficient design saves space and enhances productivity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+